| Author | Message | ||

Pressureangle |

I figured I'd start a place for in-depth discussion of what really goes on in the hole, after using up lots of pixels in some other threads. | ||

Pressureangle |

Detonation-What is it? Simply put, detonation is the explosion (as opposed to burning) of air/fuel mixture in the cylinder. Detonation has two root causes, which have an inverse relationship; Pressure and Heat. At some point, under a sufficient combination of these two a fuel/air mixture will explode. An important distinction is between 'igniting' and 'exploding'. Ignition means that it begins to burn; Exploding means that most/all available mixture 'burns' all at once. High cylinder pressure is what drives the piston; more is better. However, after a certain point these pressures can exceed mechanical limits of the engine materials, lubricants, etc. Detonation causes extremely high pressures, and causes them very abruptly. Worse yet, detonation occurs early in the power stroke, before the crankshaft angle allows much leverage-the piston can't move away fast enough, trapping the extreme pressures long enough to do damage. (this is why detonation is usually heard at low RPMs) Let's look at the two roots. Heat is normal and usually well-controlled by the engineering. Pressure is the same. When we change the conditions inside the Combustion Chamber (CC) we change the point of detonation. The whole point of adding static compression with domed pistons, bigger cams and carbs and exhaust, is to add cylinder pressure at higher RPMs where the pressure has less time to do its work. When the pressure becomes too high at normal heat levels, detonation occurs. OTOH, abnormal heat may be present-CC deposits, poor valve heat shedding, too hot spark plug heat range. Too much heat with normal pressure causes detonation. In a perfect engine, the cylinder pressure would remain just below the pressure/heat threshold of detonation for the entire power stroke-obviously, this is a physical impossibility. So what we do is make the cylinder pressure as high as possible at the point where the piston has the most leverage against the crankshaft, ~20* ATC. Cylinder pressure is generated by a few things-compression by the piston displacement, and cylinder filling efficiency through the intake tract (which itself is a function of RPM/Cam timing/port flow) and a little by exhaust pulsing. These things before ignition may never achieve enough pressure to ignite-so we add a source of ignition, a spark. This ignites the fuel in the plug gap, which burns and in turn ignites the adjacent mixture, until there is no more adjacent mixture left. As the mix burns, it expands creating pressure. This drives the piston, but it also drives the remaining unburned mixture; as the pressure increases, so does the heat. At some point, usually in an area farthest from the spark plug, the mix crosses the H/P threshold and explodes. Soooo...we adjust the timing of the ignition to bring the peak cylinder pressure right to the edge of detonation at ~20* ATC. The reason we need a timing curve is that the time available to build that max pressure becomes much shorter with increasing RPMs. The burn takes time, and the higher the RPM the more degrees the crankshaft rotates within the burn time-we have to get a head start. You can see now why an engine which does not detonate on the dyno may detonate after a few hot laps-you've added more heat over time and crossed the threshold. | ||

Ezblast |

So thats why on hot days when I go to the higher ignition curve I'll get detonation, unless I add octane boost. Tnx. What could I do to not have to add octane boost and still run the more advanced curve - retard the static timing a bit - a couple degrees? GT - JBOTDS! EZ  (Message edited by ezblast on May 03, 2006) | ||

Pressureangle |

That's difficult to answer without seeing the curves and knowing at what rpm/load the detonation occurs, but the quick answer is no. Retarding your static timing may eliminate the detonation, but it will also affect the entire curve, retarding the timing throughout. You may notice a lazy idle, unresponsive low rpm, weaker way up. If you have the available curves graphed, just choose the one with the least advance where you have the detonation, with the most everywhere else. Generally, though, electronic ignition modules have a static timing line, an advance ramp, and max timing; within the same box, changing settings only changes the rpm at which the timing advances without changing the timing at idle or full advance. Without graphs, you can only use a timing light and your tach to see where full advance is. Anybody have those graphs available? | ||

Ezblast |

The curves are the installed SE units for the Sportster/Blast - it is said that the 5th curve matches a stock Blast leaving 4 more to go up from - on a hot day I can get detonation from 6 up - lol - the plus side is that it is programmable if I get the Crane Cams ignition download cables to hook up to a pc, and get a good map to download from a fellow hot-rodder. This means that you probably already have said maps - GT - JBOTDS! EZ  | ||

Berkshire |

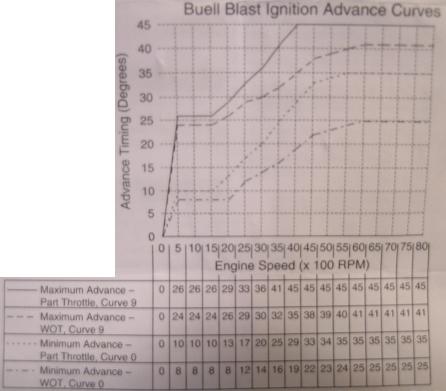

This is what comes with the SE module:  I can email a higher resolution pic if needed. | ||

Berkshire |

It looks like you could adjust the TPS to force the WOT advance curve to kick in at a lower throttle opening - basically "trick" the module into thinking you're at WOT, when you're really only at 70%, for example. If the detonation IS at WOT, then make sure you're not running lean, and don't use a spark plug that is any hotter than the minimum needed to keep from fouling it. If all that stuff is okay, then you've just reached the limit of how much timing you can run. Programming custom curves could help if the problem only happens at specific RPM, but if it's at all RPM's, then the "custom" curve would pretty much just be like using a lower setting on the SE. If the problem is more at higher RPM's, you could try advancing the base timing, and running a lower setting on the SE. change to cams with more duration!  seriously - closing the intake valve later will reduce the effective compression ratio, and make more top-end power! Engines with cams that are too "small" for their compression ratio will have trouble with detonation. Also, achieving maximum timing advance is not the holy grail of tuning - with the old setup on my mustang, it ran fastest with 14 degrees base timing. I could advance it as far as 18 degrees without detonation, but it ran slower when I advanced it beyond 14 deg. I think not needing as much timing is a characteristic of modern "swirl" head designs. | ||

Sarodude |

Swirl head designs? I remember those. The kid's hair would always stink, though... -Saro | ||

Joey |

I have technical information that I need verified. If any of these are wrong, someone please correct me. 1: When the hall-effect sensor first reaches the gap in the timing cup, the LED on the ignition goes on. 2: Ideally, this is TDC. 3: Degrees of advance are the number of crank degrees before the LED goes on, and the number of degrees before TDC, that the spark occurs. 4: The timing cup turns 180 degrees for every crank revolution. If I was an ignition module, and I wanted to know how fast the engine was turning, I would watch to see how long my LED stayed on. If I knew how many degrees the timing cup rotated during the on time, I could think to myself, "Ok, in n miliseconds, I must tell the coil to spark." This brings up the following question: How many degrees of rotation is the gap on the timing cup? I'm hoping someone knows, so I don't have to take my ignition module out of my Blast, find a protractor, and measure it. Otherwise, I will. On another thread, I talked about what I was learning about putting EFI on my Blast. I figured I'd start small and look at the ignition feature of the ECU first. The ECU is on a circuit board that is 4x6 inches. This means I'd have to find a place to park it. I contemplated the ignition module Swampy sent to me. I asked myself, "What would it take to make the ECU fit in the same place?" I then answered myself. People where I work started to look at me funny at this point. Here's what I'm thinking. There's a small processor that MicroChips makes. It's very small, and completely capable of the ignition advance thought process I layed out above. I could use the advance curve shown in Berkshire's post as a baseline. It seems there are two choices in advance: Partial throttle and WOT. That seems limited. I would make a matrix that creates 8 or more curves, which would be selected according to throttle position. The TPS is not an on/off switch--it's a variable signal. I could take that signal to select the proper timing curve. Now I find myself thinking about EZ's quandary about higher temperatures causing detonation. It would not take much to add a temperature sensor that would make minor adjustments when it's really hot outside. So, for this to work, I need 1: a power circuit to bust the 12V down to the proper voltage for the processor, 2: a circuit to interface the hall-effect sensor to the processor, 3: a circuit to interface the TPS to the processor, 4: a circuit to interface the bank angle sensor to the processor, and 5: an output circuit to drive the ignition coil. Wow. If this works, would it be worth it to fellow Blasters if I charged $150? What if I included a way to reprogram the advance curves? | ||

Sarodude |

Joey- Suggestion: Don't constrain yourself to how things are right now. For example, you mention WOT vs Partial curves. Essentially 2 curves. This is not a good choice since the Blast has a proportional TPS sensor and you could do a single 3D ignition curve instead of a pair of 2D curves - which is what we now have. That's my first suggestion. Also, instead of measuring degrees of rotation that the timing slot is cut, why don't you just see how many degrees of LED ON / OFF you have. That's probably a better indication of what the LED sees as opposed to what your eye or measuring tool sees. -Saro (Message edited by sarodude on February 08, 2007) | ||

Joey |

Sarodude! I think it would be easier to measure the timing cup than to figure out how many degrees I just turned the engine by turning the rear tire.  Read it again! I mentioned a matrix of 8 or more curves. Read it again! I mentioned a matrix of 8 or more curves.  How about we take this another step further? In the chart above in the partial throttle curve, it lists 29° at 2000 RPM and 33° at 2500 RPM. It doesn't take a lot of math to figure out something between 29° and 33° when the RPM is between 2000 and 2500. I had another thought. I'll include a serial output that sends the current RPM to anything that might be listening. I'll set up another circuit card with a display that simply displays the numbers it receives. Tach! | ||

Buellistic |

"i" set my timing with the timing mark just coming into the rear of the timing plug hole !!! Lets sound off and tell us all how you'll set your timing ??? In BLASTing LaFayette | ||

Joey |

Timing adjustments will be the same as they are now. | ||

Sarodude |

Joey- Tach Suggestion: CAN - Controller Area Network. Might be too much work though... I know there are CAN enabled displays out there - so work a little here and save a little there - maybe... Honestly, it seems like you'd be better of with MegaSquirt or MicroSquirt hardware and custom firmware. The temp sensitive ignition is a cool idea. The RPM output seems like a cool idea. Heck, you could send TPS and WideBand O2 out that port - and log. I'm sure more cool ideas are bound to pop up - many of which may be simpler to implement on existing, tried, tested hardware. As far as the 8 curves go - just interpolate between them and you're all set. -Saro | ||

Reepicheep |

I have a wideband 02 sensor that likely has a bad pre-heater element, but that is otherwise functional, that I will sell you for one third of retail price  (just gotta pull it out of my Sienna and put the new one in...) | ||

Joey |

Right now, ignition is my goal. Custom firmware is more difficult for me than the hardware. I already have the schematics and such floating around in my head. The megasquirt hardware just won't fit in the same spot as the stock ignition. The MicroSquirt may find its way into my Blast next year, though. CAN sounds like a really good idea! It won't increase my component count too much, and it will leave room for expansion. Researching ... Reepicheep! I'll keep that in mind. It would be an excellent tuning tool. Will an O2 sensor work if it is just jammed up the tailpipe, or does it have to be mounted close to the engine? (Message edited by Joey on February 08, 2007) | ||

Swampy |

I can tell you that when the LED goes off, the bike is at TDC. That is how the static timing is set up. I believe the ignition module does the rest. How interesting! | ||

Swampy |

I can tell you that when the LED goes off, the bike is at TDC, that is how the manual says to set the static timing. I find that when I check the timing with a light the the timing mark is in the window. I believe the ignition module does back?/ forward? calculating to get the timing at the correct spot. How interesting! | ||

Joey |

When it goes off? I thought it was when it went on. Ok! That makes it easier, actually. I'm researching microcontrollers right now. I was looking at an 8-bit chip, but I think a 16-bit chip would be better for handling the timing and advancing math. | ||

Swampy |

Yes, it seems to fly in the face of all reason and past methods, but if you check what the manual says, the light is just going off at TDC. I have done this a couple of times. I think it is set like that so the module can base the 2 different advance curves. | ||

Joey |

I just requested a couple of sample processors. Once they get here, I'll start working on the prototype. It will probably be mounted under the seat ultimately, while I test everything. Once I have it working reasonably well, and I can't think of any other modifications, I'll make a module that will (hopefully!) fit where the stock ignition goes. I was thinking about the gap in the timing cup. It seems to be something like 28°. I also was thinking that when the timing gap passes through the hall-effect sensor, the cup is probably rotating more slowly than at other times. That means I can't just multiply the time by how much longer it should take to get to whatever the timing advance is, especially at idle. At higher speeds, this is likely to become less of a factor, but for developing, I had to come up with something. So, I figured I needed something to keep track of how fast the timing cup was moving. Here's what I came up with.  I'm going to attach a reflective sensor close to the wheel so the processor will know just how fast the wheel is moving. Each change corresponds with 10° of crank rotation. More details when I start actual construction. Thanks again, Swampy! | ||

Mmelvis |

If you are looking to do a simple counter circuit you can pick up the pulses off the stator before the input to the voltage regulator on pin d or f. This is how some tachs work for diesel engines. http://www.vermontficks.org/dtachd.htm Link above gives the theory | ||

Joey |

I'm not looking to do a simple counter circuit. I'm looking to replace the stock ignition with one of my own design. The pattern in the timing cup is just for helping me set the whole thing up. Once I get it working, I won't need the timing pattern. | ||

Reuel |

Here's one for I/C timing.  The engine has the most power for the spark advance slightly past the knock point. So, to get the results I wanted, I have to figure out knock sensor technology. From what I've read, it isn't as simple as a signal comes when it knocks and doesn't come when it doesn't knock. Wish me luck! The engine has the most power for the spark advance slightly past the knock point. So, to get the results I wanted, I have to figure out knock sensor technology. From what I've read, it isn't as simple as a signal comes when it knocks and doesn't come when it doesn't knock. Wish me luck! | ||

Fast1075 |

I haven't had any detonation problems with my bike yet...but it is still stock. I take care to use only high quality fuel for one thing (minor cost issue since it gets seriously killer fuel economy)..I am assuming that the detonation issues are mainly on modified engines, or perhaps under conditions I haven't seen with mine. In any case, one item I ran across is the issue of poor quench in the stock engine. Poor quench is a major player in detonation, especially when the tuning combination causes excessive cylinder pressure...poor quench can cause excessively rich fuel/air mixture in areas of the combustion chamber...the overly rich areas have a considerably lower critical pressure...on a P3 where the engine spends a lot of low(er) rpm, WOT condition, the V.E. is such that cylinder pressure easily exceeds critical....the nature of the air cooled engine and uneven heat distribution in the combustion chamber and cylinder certainly are no help either... I would suggest (as I will be doing when the need arises) at the next top end refreshment, the quench issue be addressed either by modifying the head or by changing it to a more quench compliant variety..along with good piston dome design that provides the required C.R. without shrouding the chamber. It was mentioned that changing cams will help...any changes that add more duration and overlap will give more blowdown...this results in a smaller trapped volume, reducing the cylinder pressure at lower rpm (less chance for detonation)..the trade off is cylinder pressure is directly responsible for power output...hotter cams yield a softer bottom end...but the effects of intake and exhaust tract tuning come into play at higher rpm yielding increased V.E. and more power. We have to make the best of what we have...I doubt anyone is going to design and produce a pent roof 4 valve head with 16 degree included valve angles...that will fit on a P3...  Here's a question...ever see a normally aspirated Top Fuel Harley up close?? THREE spark plugs...the pistons have such MASSIVE domes, they are needed to control the flame front to help hold the detonation demon at bay... | ||

Reuel |

Somebody here has a 4 valve Blast. I just don't remember who, or the details. What can you say about multiple spark ignition? Does it actually help? I could stick that in my timing checks to see how it affects RPMs. As far as improving quench and all that, when I get money in hand, I'll be calling Revolution Performance and asking them all those questions. What about porting? I was reading about port modification at a race website. This guy was opening the port around the valve stem, but actually filling in on the opposite side, reducing the port size to 70-80% of original size. He claimed an increase in total useable horsepower, with only small losses of peak horsepower. He has lots of email posted that describe people trying it and having success. The physics of it all seem sound, too. | ||

Fast1075 |

I have run two different ignitions on my dragbikes (Import motors) that have the multi-spark feature...the MSD system and the Schnitz system...the systems help with keeping the fires lit and the plugs clean at low rpm (up to approx 6K) a useful function with long duration high overlap cams which tend to load up at low rpm. The porting is a worthy plan...the production engines have a high cost saving bias where the beancounters often over rule the engineers...you end up with a head that works well for putting around and the bean counters are happy...as for modifications...what you need to shoot for is a balance of flow and velocity through the ports...maximum flow is limited by velocity however..the flow must remain subsonic..one thing that is not readily appearant is that if you take a port and stretch it out straight, the portion where the port turns into the bowl is actually hourglass shaped...the reason for this is as the port makes the mandatory turn, you need to increase the velocity...the shape accomplishes that...changing the shape of the port is fairly common...one good example is the older Suzuki GSXR engines...in order to gain velocity to keep the torque curve usable in road race applications, the ports were commonly welded or epoxied up...in any case the trick to porting is to remember that what may seem to be intuitive may lead you down the wrong path...if you want to DIY...you are best off having a known pattern to follow...the floor of the port where it turns into the bowl especially on the intake is very easy to mess up, causing turbulence which kills flow...a good clean up and smoothing of the basic contours is easy and is something you can do with a good die grinder and assortment of bits and sanding rolls...just don't get into the seats. | ||

Monteflow98 |

No idea where to post this. This site is kinda confusing. When I ride the bike, I sometimes hear a knocking sound. I hear it when I ride the higher RPM's. I'm trying to get a tach so I can see where in the RPM's it is the worst. But if i'm doing close to 45 in 3rd gear I hear it. Does anyone else have the same problem? Also, sometimes when I take off from a start I hear a clanking sound. Both could just be that it's a harley motor? I also replaced the rockerbox gasket and the top rubber gasket. Could I have not tightened something? Or maybe put something in wrong? Bike runs great, and when I baby it, I hear almost nothing. | ||

Reuel |

Have you checked your timing? | ||

Ezblast |

Concur | ||

Swampy |

That and your engine sprocket nut. They can come loose and they don't make alot of noise before they really mess things up. | ||

Sarodude |

There's something else I think happens on the Blast..... At really low revs I get the feeling that the slide actually clacks closed with the extremely unsteady flow of that single at low revs. I don't KNOW that - but I sorta suspect it. -Saro | ||

Reuel |

If the slide goes too far shut, you're likely to get an overly rich condition. Next time you have the air cleaner off, start it up and watch the slide. It does seem to vibrate in time with the engine when you first open the throttle at idle. That would be natural, though, since it only gets vacuum to open it during the intake stroke. Once I'm done with this 12 hour night shift stuff, I'll be able to take some time to watch the O2 levels... |