| Author |

Message |

Twisteduly

| | Posted on Saturday, July 23, 2016 - 01:00 pm: |

|

OK, It seems like we have a discussion going. And some light has been shed.

Some variables I see are the method of getting the rear wheel of the ground ( race stands vs jacking point method).

Jacking the bike up unloads the swing arm entirely whereas lifting via the swing arm still has load on the shock.

Rear sprocket and swing arm pivot is the arc of travel. The crank sprocket and the tensioner make up the remaining variables.

As the swing arm moves down (unloads) the belt has more contact with the tensioner (belt wrap) in theory it should be tightest.

I watched a u tube vid from a fellow member and he did all the work for a belt r&r with the bike on race stands except for the ability to swap the belts due to the race stand. He immediatly switched back to the race stand for all else.

I'm thinking a ratchet strap to slightly compress the shock just might make a road side repair much easier. |

1313

| | Posted on Saturday, July 23, 2016 - 02:14 pm: |

|

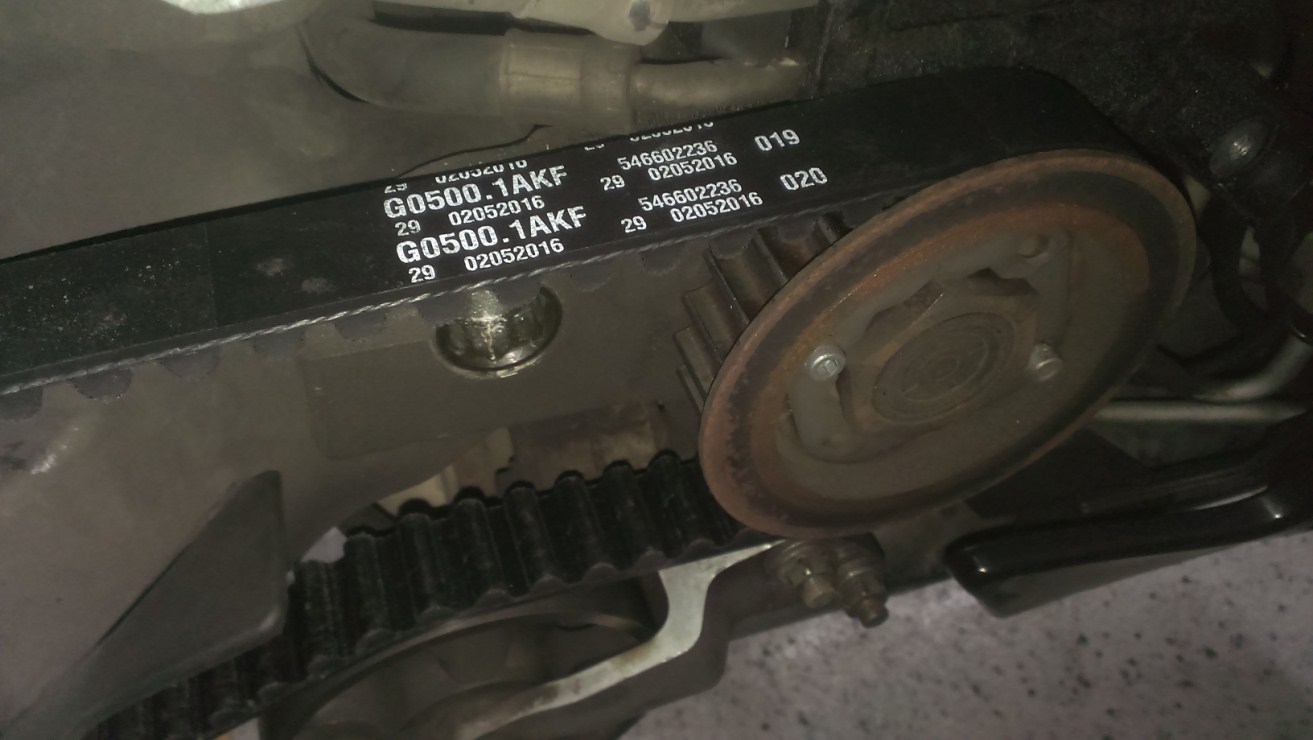

•••• YEAH! SUCCESS! FINALLY!

No Buell logo, see...

Hope it's a LONG time before I have to do another. First one failed at 23,273 - borrowed a used belt from a fellow C3er - installed new AKE belt at 24,037. I thought my (self-imposed) change interval was 20,000 until I did the math on the next new (AKF) belt at 49,464. Now at 70,585 with an AKG belt:

I was getting such good (OK, better than 'normal'...) mileage coming back from Homecoming - which is apparently when the rotor side bearing failed.

I sure wish I didn't have my '98 S3T Defender occupying my Handy Lift cause it would've been MUCH easier doing it there than on the floor. Froggy's too old to ride far distances, and I'm too old for this work on the floor shit!

I know who did the computer calculations that placed the tensioner on the original XB's. We we're outside smoking one day and he mentioned that his computer was bogged down doing the math. It's a quick assumption that he was involved with the Uly, but since I don't know for sure I can't give him my choice words about how much *FUN* this task was...

For a data point, Pit Bull rear stand - with momentatnious jack under muffler to do the belt exchange - used for this *FUN* task. Result = still a BITCH!

With new

- AKF belt

- rear wheel bearings

- rear wheel spacer

- rear wheel bearing seals

- rear axle

- rear rotor

- rear brake pads

- tires front and rear

- front wheel bearings

- front wheel spacer

- front brake pads

- and soon to be new double sided tape on the rear reflector

it should be pretty much like riding a new bike.

Still haven't taken it for a test run yet (but it's definitely gotten more 'character' from this exceptional adventure)...

1313 |

Hughlysses

| | Posted on Saturday, July 23, 2016 - 02:22 pm: |

|

My experience with belts on the Uly has been mixed. First belt had substantial cracking between the teeth at ~7000 miles. Even though it was still under warranty, I replaced it on my dime and saved that belt as a spare. The 2nd belt went to about 45k miles (almost 40k belt life) before breaking. 3rd belt, installed about a couple of years ago was the latest generation, but it surprisingly showed substantial cracking at ~10,000 miles so I replaced it. The latest belt, installed about a year ago, still looks flawless after ~6000 miles.

I installed new tires last week and noticed I'm going to need to pick up a new rear sprocket soon while they're still available. A couple of chips in the powder coating on the teeth have gradually turned into several bare teeth and some of those are noticeably worn. I'd think that'll eventually cause issues with the teeth on the belt. |

Tootal

| | Posted on Saturday, July 23, 2016 - 04:29 pm: |

|

I was getting such good (OK, better than 'normal'...) mileage coming back from Homecoming - which is apparently when the rotor side bearing failed.

The fuel in Wisconsin is real gas, not ethanol. My bike got over 50 mpg coming home from homecoming several years ago. As soon as I put Illinois ethanol in it, it dropped to 43 mpg. I really hate ethanol!

My belts been on for quite a while now but I'm thinking about getting a new one anyway. Never hurts to be prepared! |

Reepicheep

| | Posted on Monday, July 25, 2016 - 10:31 am: |

|

I've always made the mounting holes on the belt tensioner a couple sizes bigger just for this reason.

It keeps the suspension from loading up the belt (wasn't a problem on my XB9SX, but it was happening on my XB12X, it might *barely* be happening on my XB12XT).

But the main thing it does is give just a little more margin to make it easier to get that belt on and off.

If it is hurting my belt life, I can't tell, as I haven't broken a belt yet (35k on an M2, 33k on the 9sx, 30k on the XB12X). |

Mbest

| | Posted on Monday, July 25, 2016 - 11:31 am: |

|

Broke three of the new belts on my '08 uly until I opened up the holes in the tensioner to take the "guitar string" tightness out of the belt.

Over 33K miles on the last belt with no issues

mike |

Ratbuell

| | Posted on Tuesday, July 26, 2016 - 12:20 am: |

|

Um...it's not that hard, fellas.

I've done a used-belt install (my spare), roadside, in half an hour, with the Buell toolkit and the bike ON THE SIDESTAND. Full-on, new-belt install on a lift (remove "spare" for re-folding and stowing, and install brand new un-stretched belt) in about the same time.

What part of it is kicking y'all's ass? |

Reepicheep

| | Posted on Tuesday, July 26, 2016 - 08:17 am: |

|

If it is the first time breaking the axle free, or if it didn't have anti-seize after the last time, that first turn can be a bear. |

Ruans187

| | Posted on Tuesday, March 07, 2017 - 10:22 pm: |

|

I thought I was almost done until the new belt didn't want to fit...Is so tight..And tensioner makes it harder...I'm using rear swingarm stand..

Axle nut is almost out, and I. About to take bike to a shop..So I don't have to fight that belt no more |

651lance

| | Posted on Tuesday, March 07, 2017 - 10:56 pm: |

|

The axle need to be out to the last step. Then mount the idler. With the idler installed screw the axle back in. |

Etennuly

| | Posted on Monday, May 01, 2017 - 01:45 am: |

|

Put my new one on today. Thanks Lance for having them!

I slid an 8" cement block under the rear of the muffler then tip the bike up on the side stand to slide a 3/4" board on top of the block. I unscrewed the axle all the way out so the wheel moves forward a bit more making it easier to get the belt on the pulley. Where the pinch bolt gap is just a little assist with a screw driver to start the axle head back in the swing arm. Did not touch idler. Using ele 3/8 impact wrench to speed up bolting I was easily done in a half hour. |

|